Bulk Solid Waste Incineration

as a Source of Energy: Environmental Success Story, Expensive Diversion,

or a Little of Both?

Prepared by Kevin Olsen for

Waste Management, Spring 2006

Professor Eric Stern

Montclair State University

The mass burning

of municipal solid waste (MSW) is an important means of cleanly generating

electricity. The waste to energy industry has made remarkable strides

in reducing the amount of air pollution emitted by its facilities. Activated

carbon injection, spay dryer absorbers, and selective non-catalytic reduction

are just three of the technologies that have cut emissions to very low

levels. But they are expensive to operate and the emissions reductions

have come at a very high financial cost. In some instances Waste to

Energy (WTE) facilities have been driven into bankruptcy by even a small

reduction in the amount of waste (and the associated tipping fees) available

for them to burn.

Critics of WTE facilities have pointed out that even low levels of emissions

are still emissions and as such they pose a health hazard. These

critics also argue that the existence of WTE plants does little or nothing

to encourage recycling. As of 2005/2006 only 30% of America's solid

waste is recycled. Certainly, there is room for improvement but the

question remains of what to do with the wastes that cannot be recycled.

The future of WTE will depend on the costs of landfills as well as the

amount of MSW recycled, reduced, or composted. There are also emerging

technologies such as plasma torch incineration, which may render the current

generation of WTE facilities obsolete. It may be that in the future,

a smaller number of WTE facilities will serve a greater number of municipalities

because the majority of solid waste will be recycled.

The discussion that follows focuses primarily on the facilities operating

in New Jersey.

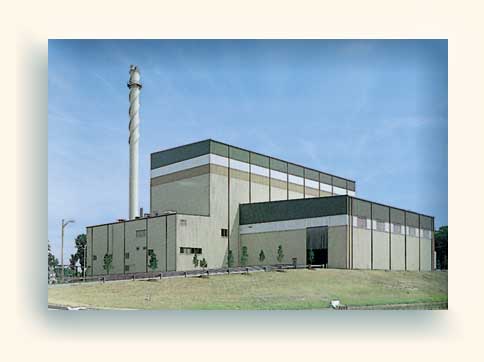

Westville NJ Waste to Energy Plant

In the 1980s the State of New Jersey mandated that each of its 21 counties build a WTE plant. Delays and public opposition meant that only four plants were constructed under this plan. Today New Jersey has five WTE facilities.

Waste to energy facilities generally fall into several categories. As

the name implies, mass burn types use large quantities of solid waste as

a fuel source. A smaller percentage of plants

are the blended fuel type. In these facilities,

solid waste is combined with another fuel type to increase its BTU value.

Table one: National

Distribution of WTE Plants:

Northeast = 42 (Vermont

and Rhode Island are the only two states without them)

Southeast = 21

Midwest = 17

Western States (including

one each in Alaska and Hawaii) = 9

Total: 89 Plants in 27

states

65 are Mass Burn type

that produces both electricity and / or steam.

10 are Refuse Derived

Fuel type where combustibles are separated from waste stream and blended

for optimal burning.

The remaining plants use

some combination of these two technologies.

Table Two: New Jersey's WTE plants:

Camden - 1050 tons / day

- Mass burn water wall - 1991

Newark - 2700 tons / day

- Mass burn water wall - 1990

Rahway - 1440 tons / day

- Mass burn water wall - 1994

Oxford (Warren Cty) 448

tons / day - Mass burn water wall - 1988

Westville - 575 tons /

day - Mass burn water wall - 1990

All New Jersey WTE plants

have a Spray dryer absorber or scrubber (SDA), most have Select non catalytic

reduction for NOx control (SNCR), and all have activated carbon injection

(CI). These technologies will be explained

later in this document.

Together they generate

a total 168 MW of electricity and burn 6213 tons of trash every day.

Ironically, communities

that use WTE plants recycle slightly more waste (34%) than the national average

of 30%. New Jersey community recycling percentages

range from 33% (Camden) to 63% Gloucester with the average being 47%.

Protestors oppose the construction of a WTE facility in the United Kingdom. Newark, in Essex County, England, is the proposed site of this facility.

Wherever and whenever

WTE facilities are proposed, they generate heated opposition long before

they generate electricity. The critics have a

number of very valid points.

The heating value of MSW

is relatively low. It takes about one ton (2000

lbs) to equal the heating value of just 500 pounds of coal. Only about 80% of solid waste is combustible.

Another argument made

by the critics is that WTE facilities do nothing to encourage recycling and

in this, they certainly have a very valid point. For

all the efforts made in the last decades, nationally, the amount of solid

waste that will be recycled is only 30% according to the Department of Energy.

Table Three: Waste

Generation among industrialized nations and percentage of waste burned

in WTE facilites.

United States - 4.4 pounds

per person per day – Burns 13% of its trash as WTE

Canada - 3.7 pounds -

Burns 8% of its trash as WTE

Netherlands - 3.0 pounds

United Kingdom - 2.8 pounds

Japan - 2.8 pounds - Burns

62% of its trash as WTE

France - 2.1 pounds -

- Burns 35% of its trash as WTE

Germany - 2.0 pounds

Switzerland - ? pounds

- - Burns 60% of its trash as WTE

The United States also

does a poor job recycling. Again the figures supplied by the Department

of Energy show that we recycle only:

57% of yard waste

49% of aluminum

26% of glass

3% of plastic

andÉ.

91% of car batteries.

Another argument made

against WTE facilities are that the ash from them is hazardous and as such

cannot be re-used in some beneficial way. The

main use of ash from WTE facilities is landfill cover (39%) and a small percentage

is used as construction fill. WTE facilities

produce 300 to 600 pounds of ash for every ton of waste incinerated. When the ash contains mercury or other hazardous materials

it must go into landfills which further increases the operating costs.

The typical WTE facility

is shown in this diagram. Trash arrives and is

transferred into the pit, also known as the bunker or sometimes as the bin. An overhead crane transfers it to the feeder from

whence it is fed into the firebox. Note that

the top of the firebox is not open to, or even close to, the stack. The flue gasses first pass through several emissions

controlling steps. Steam from the boiler powers

a turbine to generate electricity.

Some of the following photographs were taken at a WTE facility being constructed in Germany. Others illustrate the equipment typical of the plants throughout the industrialized world.

A waste bunker under construction in Germany. Note the size of the bunker as illustrated by the construction equipment.

Here is the first load of waste in the bunker

This is the waste feeder that will be installed between the bunker and the boiler

Detail of a water wall

The water wall boiler

is the most common type for WTE plants. In this

system, the firebox walls consist of hollow tubes inside which the water

is boiled. The water wall boiler is very difficult

to construct because the tubing must be bend around any openings in the firebox. In this illustration the tubes are bent so as to

allow the installation of an inspection port.

Construction of a Water Wall

The emissions control

system is what makes the WTE plant possible. Prior

to the creation of WTE plants, there was no serious effort dedicated to emissions

controls. Apartment complexes, industrial plants,

hospitals, and even private homes incinerated their wastes with little thought

paid to the environmental impacts.

At present, the cleanest

New Jersey incinerator is Rahway, which emits only 5uG Hg per cubic meter

of exhaust. This is much less than the state allowable level of 28

uG per cubic meter. Mercury source reduction is largely responsible

for this reduction.

Thanks in large part to

carbon injection technology, dioxin emissions are also very low. The

EU allows 0.1 ng of dioxin per cubic meter and US plants are below this.

Today, most dioxin from

trash burning comes from backyard incineration. Backyard burning just

ten pounds of trash produces more dioxins, furans, and PCBs than 400,000

pounds of trash in a WTE incinerator according to the New York State Department

of Health.

All of this cleanliness

comes at a price. Billions of dollars were required to achieve this

level of output. If the ash from a WTE burn is contaminated with mercury,

the cost of landfill disposal will increase the operating costs even more.

Strict pollution controls

also makes WTE incineration extremely expensive. Moving trash hundreds

of miles to a landfill is often cheaper than moving it only a few miles to

the nearest WTE burner.

The plumbing of a SNCR system

A Select Non-Catalytic

Reduction System injects urea, ammonia, or some other nitrogen containing

material into the flue gas. These molecules

react with the nitrous oxides to produce acids, which are then removed in

the scrubber. Nitrous oxides are a major source

of acid rain.

The interior of the building that houses the air pollution controls at the German WTE plant

Unloading a sulfur dioxide control system prior to installation at the German WTE plant.

Schematic of a carbon injection system. Systems like these are responsible for the dramatic drop in dioxin emissions. This particular system also includes a alkaline slurry feed. The dioxins are absorbed onto activated carbon particles that are injected directly into the waste stream. The carbon is then removed by a particulate filter / bagging operation before the gasses are sent up the stack.

Acidic gases in the exhaust are neutralized with a mist of reagent slurry injected into the Spray Drier Absorber (SDA) unit. Note the tank of lime to supply alkali material. The neutralized acids are collected and the un-reacted alkaline material is recycled back into the scrubber.

A final word about

WTE plant costs:

CSX trash

train eastbound at Point of Rocks, MD.

Where is this

trash going? Is it destined for a landfill hundreds

of miles away as opposed to a local WTE plant?

Why is it

not being recycled?

In either

case, let us hope for the sake of the crew that there was a steady stream

of air carrying the odors away from the locomotive.

Photographed

by Ethan Barlow, June 23, 2003.

Environmentally sound

and economically viable WTE operations require a steady supply of burnable

refuse arriving at the plant on a regular basis. When

New Jersey counties originally funded their WTE plants, it was assumed

that there would be no shortage of materials for them to burn and that they

would pay for themselves by saving the county the costs of landfill disposal

for the wastes. Sadly things did not work out

that way.

Laws were passed that

mandated that all non-recycled trash generated in a county had to be incinerated

in the host county WTE facility. But the federal

courts later ruled that the transportation of trash was a form of interstate

commerce and as such was constitutionally protected.

WTE plants were forced to compete with out of state landfills and

even the recycling programs operated by the host county.

Even a small reduction in material flow was enough to send several

plants into bankruptcy.

The contracts signed between

the counties and the operators of the plants placed all of the risk on the

public agencies. If there was not enough material

for efficient burning, then the host county would be responsible for reimbursing

the plant operator for lost electrical generation revenues. This arrangement has been used as an argument against

additional WTE facility construction in other parts of the United States.

Congress did not address

the issue of interstate waste transport. Laws

that restrict the export of waste materials across state lines might have

made WTE plants more economically competitive with landfills.

WTE Timeline:

1980s The state

of new Jersey mandates that each county should build its own trash incinerator.

Meanwhile the Federal

Courts declare that governments cannot restrict the flow of wastes.

This means that the individual counties cannot prohibit the export of garbage.

Congress does not address this issue.

1988 Warren County

incinerator opened.

1989 WTE Mercury

Emissions exceed 89 tons annually.

1990 Clean Air

Act legislation specifically addresses Dioxin emissions from WTE plants.

Mercury use in the United

States at 2000 tons/year

Newark and Westville WTE

facilities opened.

1991 Camden WTE

plant opened.

1993 New Jersey

adopts legislation to cut mercury emissions 90%

1994 Rahway WTE

facility opened.

1997 Trash shortage

requires 2 billion dollar bailout of Union and Camden County facilities.

2000 Dioxin emissions

in US WTE plants drop 99.7% from 1990 levels. Total dioxin emissions

in the US decreased by a factor of 10.

2001 Rahway reduces

mercury emissions to less than 5 uGrams / cubic meter of exhaust.

The state limit on emissions is 28 uGrams / cubic meter.

2004 Largely due

to source reduction, WTE mercury emissions drops below 1 ton.

2006 Mercury use

in the United States drops to less than 500 tons annually.

The Future?

Much will depend on landfill capacity and tipping fees. The future of

WTE technology will also be governed by the amount of material recycled and

composted. While improved incineration technologies

such as plasma torch systems promise to make WTE plants more efficient, other

technologies such as biodegradable packaging and aggressive MSW composting

might make them less necessary.

In the final analysis,

there will always be some trash that can neither be recycled or reduced.

The debate will be whether we use landfills or incineration to dispose of

it.

But that is a debate for

another time.

Note: Much of

the information presented in the document comes from the

The 2004 IWSA Directory of Waste to Energy Plants,

Integrated Waste Services Association, Washington, DC, 2004.

Internet resources include the Department of Energy, Garden State Environet,

New Jersey Institute of Technology, and the New York State Department of

Health.